Contamination Prevention

Early detection + prescriptive actions to prevent excursions.

Start with one module or deploy end-to-end across your cleanroom environment.

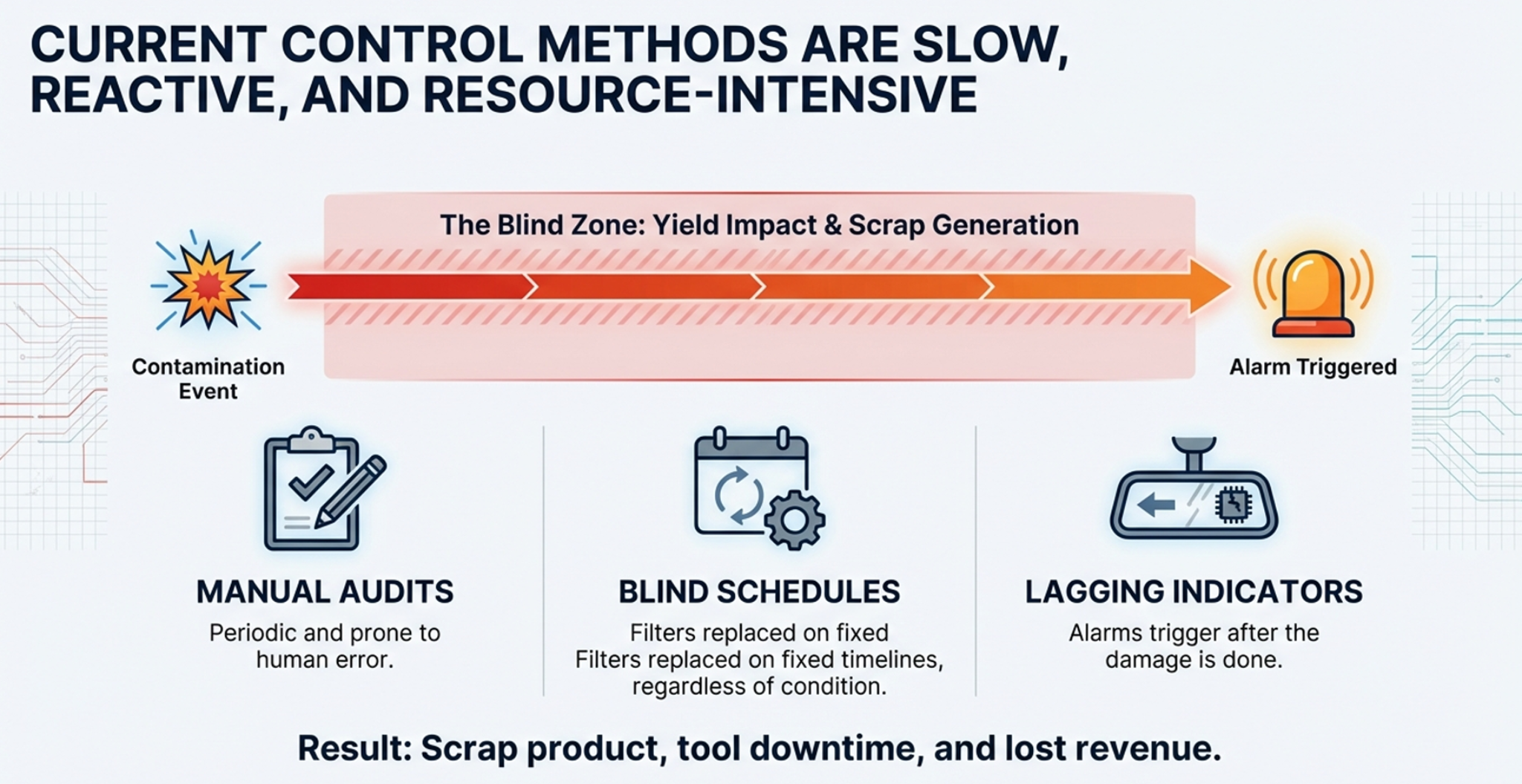

Risk is often invisible until it impacts yield. Traditional audits and periodic studies are slow, and alerts can arrive too late.

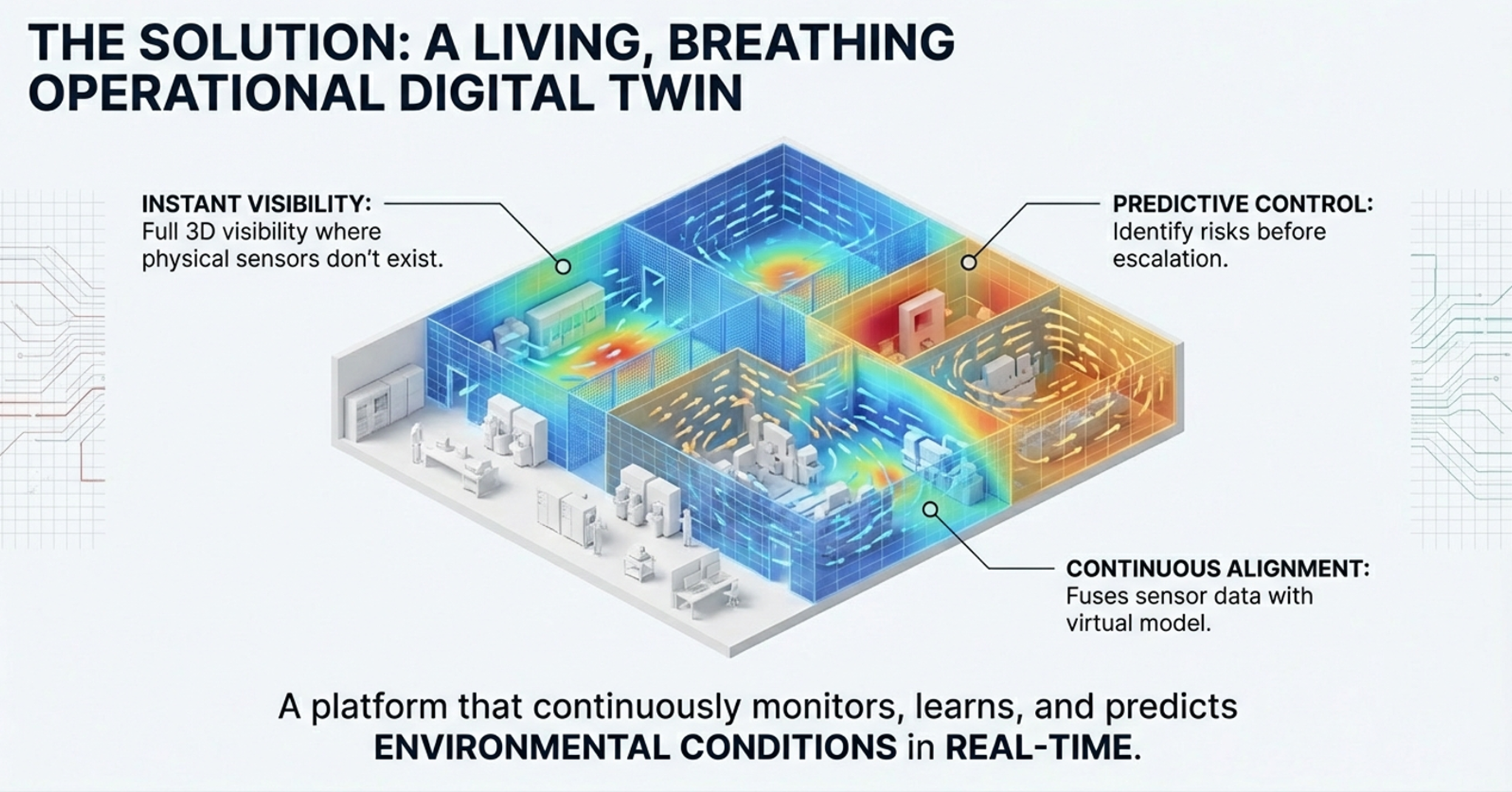

A live operational digital twin that fuses sensor data + physics + AI to monitor, predict, and recommend actions continuously.

Early detection + prescriptive actions to prevent excursions.

Health forecasting for filters and critical equipment to reduce surprises.

Run “what-if” scenarios to tune airflow and filtration for efficiency.

Value for fabs and filtration OEMs—monitoring, validation, and improvement.

Periodic audits, fixed replacement schedules, and lagging indicators often detect problems after damage is done. TwinFab shifts teams from reactive response to predictive control—powered by an operational digital twin.

Start with contamination visibility, filter health forecasting, or scenario simulation. Expand over time into a unified live operations layer across the cleanroom.

Zone risk maps, virtual sensors, and anomaly detection.

Excursion risk, yield impact trends, and early warnings.

Energy-efficient airflow, setpoint tuning, and validation.

Hybrid physics + AI engine powering real-time digital twins.

TwinFab blends validated physics with fast AI surrogates to keep a high-fidelity twin synchronized with reality—then turns that into predictions, alerts, and what-if analysis.

Click any architecture block to see a short explanation.

Reduced-order models capture airflow and contaminant behavior with near real-time performance.

Ingest sensor, SCADA, and MES signals to align the twin and create “virtual sensors” between gauges.

Designed for enterprise deployments with security-first architecture and integration-friendly APIs.

Experience instant visibility and predictive control. Adjust the fab parameters to see how the digital twin surfaces risk hotspots and optimization tradeoffs.

Lower speed saves energy but can increase contamination risk.

Simulate aging filters to test predictive alerts.

Illustrative range used in AMC filter validation demos.

Higher flow can change breakthrough timing and outlet behavior.

The digital twin estimates airflow stagnation points and particle accumulation (Warning/Critical zones) based on your settings.

Estimate the benefit of reducing contamination-related yield loss through earlier detection and intervention.

This calculator is for estimation. It does not include pricing and is not investment material.